Visiting Krayon in Neuchâtel

Second visit for the sunrise

This is our second visit to Krayon’s atelier on Lake Neuchâtel’s shore since 2024. We arrived early at 6:30 in the morning this time, hoping to see the sunrise from the balcony that inspired the brand’s iconic timepiece.

An overcast sky hid the sun above the lake, dashing our sunrise hopes—but disappointment faded quickly with Krayon’s Anywhere.

And this is exactly the point of this timepiece - even with the sun obscured, it accurately displays when the sun will rise beyond the lake’s clouds, beyond telling time, it bridges what we see and what we don’t, keeping us connected to the rhythm of our planet, whatever the weather and where we are.

The Early Team

Early morning light filtered into Krayon’s lakeside atelier, with watchmaking benches not fully occupied. Yet those present focused intently. Heads bent, eyes on tiny components, just dedication, showcasing Krayon’s watchmaking patience and precision. As sunlight hinted through clouds, craftsmen stayed rooted in tasks. In that moment, the atelier was where art and engineering converged, step by step.

Human Touch

Every Krayon timepiece is assembled and adjusted entirely by human hands—each delicate step carried out with the care and precision that defines master watchmaking. There are no shortcuts here; every component is positioned, calibrated, and refined through skilled manual work, ensuring that each piece bears the mark of craftsmanship rather than mass production.

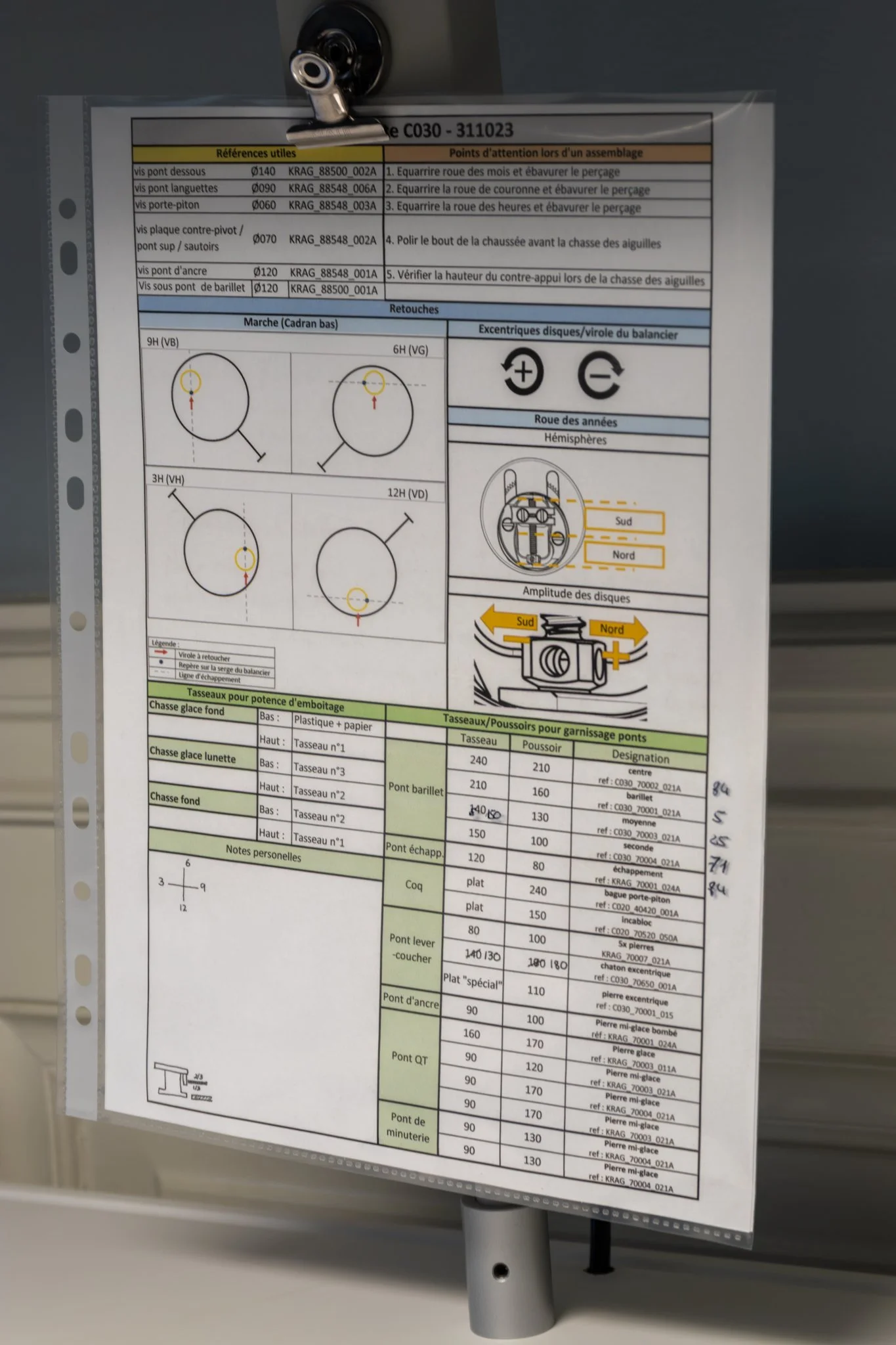

Keeping Up To The Highest Standard

Beyond the hands-on craft, every timepiece must adhere to a strict standard procedure, one that is familiar to every watchmaker at the atelier. This standardized process acts as a non-negotiable framework: from checking the alignment of gears to testing the accuracy of timekeeping, every detail is measured against the same high benchmark—one that meets, and even exceeds, the rigorous standards of the watchmaking industry.

Pallet Jewels Adjustment

In the precise world of watchmaking, where even the tiniest component can determine the performance and reliability of an entire timepiece, this is a specialised machine designed for adjusting the depth of the pallet stones, in order to ensure the correct distribution of energy from the gear train to the balance wheel, at the same time to ensure the safety features in the escapement work well to avoid the watch stops from external shocks, which is something we take it for granted, but actually a big challenge before the advent of the Swiss lever escapement.

Adjusted To 6 Positions

Every Krayon timepiece undergoes meticulous adjustment across six different positions— a precise process designed to minimize any positional error that could affect timekeeping accuracy. This careful calibration is the key to why Krayon’s watches achieve chronometer-level precision, even without relying on complex mechanisms like a tourbillon or an overcoil hairspring.

For Krayon, this balance of accuracy and simplicity serves a critical purpose: it allows their timepieces to depict sunrises and sunsets with exceptional precision, a core function of models like the Anywhere. At the same time, avoiding overly intricate components ensures the watches maintain a slim, elegant profile - blending technical performance with aesthetic refinement.

High-Precision Weighing Scale

In precision watchmaking, every internal component has a specific purpose. A watch works accurately and stably only when all parts are in the correct position, good condition, and precise weight - this "three-correct" principle is core to high-end watchmaking, and Krayon’s commitment to it is seen in its atelier’s high-precision scale.

It measures to four decimal places of a gram, detecting even tiny weight deviations. Because tiny components like this may have a significant difference in weight between freshly coming out from the lathe, and finally adjusted or finished with various decorations, therefore, watchmakers weigh the components, ensuring they meet design standards - only qualified parts enter assembly.

Dust Inspection

At Krayon’s lakeside atelier, every timepiece requires critical, time-consuming defect and dust inspection - taking a day to weeks, depends mostly on the watchmakers’ sharp eyesight and craftsmanship, plus occasional luck.

Dust and particles are everywhere in our world. Even with meticulous creation, unwanted particles may slip into timepieces from time to time. When this happens, the watch has to be carefully disassembled, and the inspection process restarts - all to ensure flawless condition before reaching their clients’ hands.

This repeated effort follows one principle: guarantee every Krayon timepiece meets top perfection standards. Watchmakers check every detail (e.g., hand misalignment, dial dust) that risks quality. It reflects respect for craftsmanship and a solemn commitment to trusting customers.

Krayon’s Sanctuary of High-End Finishing: The Artistic Transformation

Not all watchmakers access this "sanctuary" - only those mastering high-end decoration art deserve to sit here. Their tools feel soulful: delicate Cotês de Genève, exquisite perlage, precise anglage - each process holds decades of skill. With gentle toolwork, cold metal components gain warm luster, patterns neat and detailed enough for strict scrutiny.

At these altar-like workbenches, Krayon timepiece components turn from precision parts to artworks. These finished components go beyond mechanical functions, carrying the brand’s aesthetics and craftsmanship. Even hidden in the watch case, they keep artistic texture - this is Krayon’s take on high-end watchmaking, a craftsmen’s romantic chapter where mechanics meet aesthetics.

Perlage

Perlage is key to highlighting component refinement. The core tool for this classic decoration is a specialised machine fitted with abrasive sticks of different grades; unlike complex precision equipment, it uses precise grit size and pressure control to give metal surfaces a pearl-like soft luster and texture.

Even under a magnifying glass, the perlage’s delicacy holds. This technique proves Krayon’s dedication to invisible details, infusing every timepiece with craftsmanship warmth—even in unseen parts.

In-House Component Holders

To get impeccable flat satin finishes on watch parts, the brand develops in-house specialised holders tailored to these components. This overly meticulous move shows Krayon’s obsession with craftsmanship precision and makes its satin finishings stand out. Flat satin finishing faces two key hurdles: achieving consistent texture and safeguarding component edges and corners from rounding. These bespoke components holders tackle these issues perfectly.

Polishing Materials

Anglage and black polishing shape components’ texture and aesthetics. A diverse but specific set of polishing materials — from polishing paste to 20-carat diamond powder — supports these processes, each playing an irreplaceable role in specific stages to deliver flawless surfaces on the components.

Krayon At The Bench

And we were honoured to have Rémi Maillat, the founder of Krayon, to demonstrate the meticulous technique of anglage in person. The result was stunning.

The Clunking Guardian Of Krayon’s Watch Quality

During our visit at Krayon’s atelier, a continuous clunking sound lingered in the background — unlike the soft grinding sounds of watchmaking tools, this sound had a regular rhythm, which sparked our curiosity. When we asked Rémi about this, he showed us the testing machine operating somewhere in the corner, which made the clunking sound, and this machine is a key part of Krayon’s efforts to ensure watch quality.

Fully assembled Krayon watches are secured into this device, enduring motions mimicking daily wear, like arm swings and minor impacts. This process rigorously evaluates two critical functions: accuracy stability, ensuring precise timekeeping despite external vibrations; and shock resistance, confirming the internal components withstand external shocks without malfunction.

Beyond that, the machine's swings and shocks double as the final dust inspection. By subjecting watches to continuous vibration, it dislodges any minuscule dust particles lingering within the movement — even those missed during meticulous assembly and initial checks. Should subsequent inspections reveal dust, the watch undergoes a second cleaning until it meets strict cleanliness standards.

The Heart Of The Krayon Anywhere

The small yet vital cam wheel of the Anywhere, uses precise mechanical logic to show exact sunrise/sunset times of a specific Earth location. Though seeming a single piece, the cam wheel is assembled from 14 small precision parts. Notably, it has the longest adjustment screw in the watch which is very hard to produce.

Extremely tiny gears compared to the tip of a ballpoint pen. The camera can’t even focus on it!

The big and small cam wheels of the latest Krayon Anyday, which is the world’s first mechanical agenda on the wrist. The wearer can read the whole month with a glance.

The Krayon Anyday comprises of 378 components in its 9.5mm-thinness case with an elegant 39mm diameter. Here are just few of those components.

The world’s first mechanical planner watch - The Krayon Anyday.

We sincerely thank Krayon for welcoming us to its atelier and once again giving us an eye-opening experience of high-end watchmaking excellence.

Every detail showed Krayon’s passion for turning parts into art. This experience deepened our appreciation for its craftsmanship, and we’re grateful for the chance to witness such extraordinary watchmaking expertise.