Visiting Jaquet Droz in La Chaux-de-Fonds

Jaquet Droz’s factory is on Allée du Tourbillon in La Chaux-de-Fonds—a Swiss watchmaking heritage city visited by The Lavish Attic team last September. Nestled in the Jura Mountains, this UNESCO site is known for its 18th-century light-optimized urban layout and global horology cradle status.

The brand has deep local roots: founder Pierre Jaquet-Droz (born 1721 here) opened a 1738 workshop, pioneering “emotional horology” with automata and timepieces that charmed European courts.

Today, the factory continues this legacy, blending 18th-century craft with modern innovation (e.g., reimagined Grande Seconde) and local expertise. For Jaquet Droz, it’s more than a factory—it links to centuries of horology-shaping craftsmanship.

The Magician

At the entrance of Jaquet Droz’s factory on Allée du Tourbillon, the brand’s prowess in crafting extraordinary automatons takes center stage—thanks to the “Magician” automaton figure.

This life-sized humanoid automaton mesmerizes audiences with its masterful performance. With nimble hands, it skillfully conceals and reveals Jaquet Droz watches between two cups. But the magic doesn't stop there. A closer look reveals that the automaton can secretly store up to eight watches, seamlessly incorporating them into the act for a continuously enchanting horological show.

Yet the automaton’s greatest allure lies in its mystery: no one has fully unraveled the secrets of its internal mechanism. This clever, enchanting piece isn’t just a decorative welcome—it’s a vivid nod to Jaquet Droz’s centuries-old legacy of blending horological precision with whimsical, artful automata craft.

Tiger Sculpture

This fully mechanical piece works simply: press a button, and it opens to present 2 Jaquet Droz watches inside. It also stands out for customizability—such display sculptures can be tailored to clients’ desires, blending watch presentation with personalized art.

Like the factory’s “Magician” automaton, the tiger sculpture is more than decor; it vividly shows Jaquet Droz’s centuries of expertise in merging mechanical precision with creative, client-focused design.

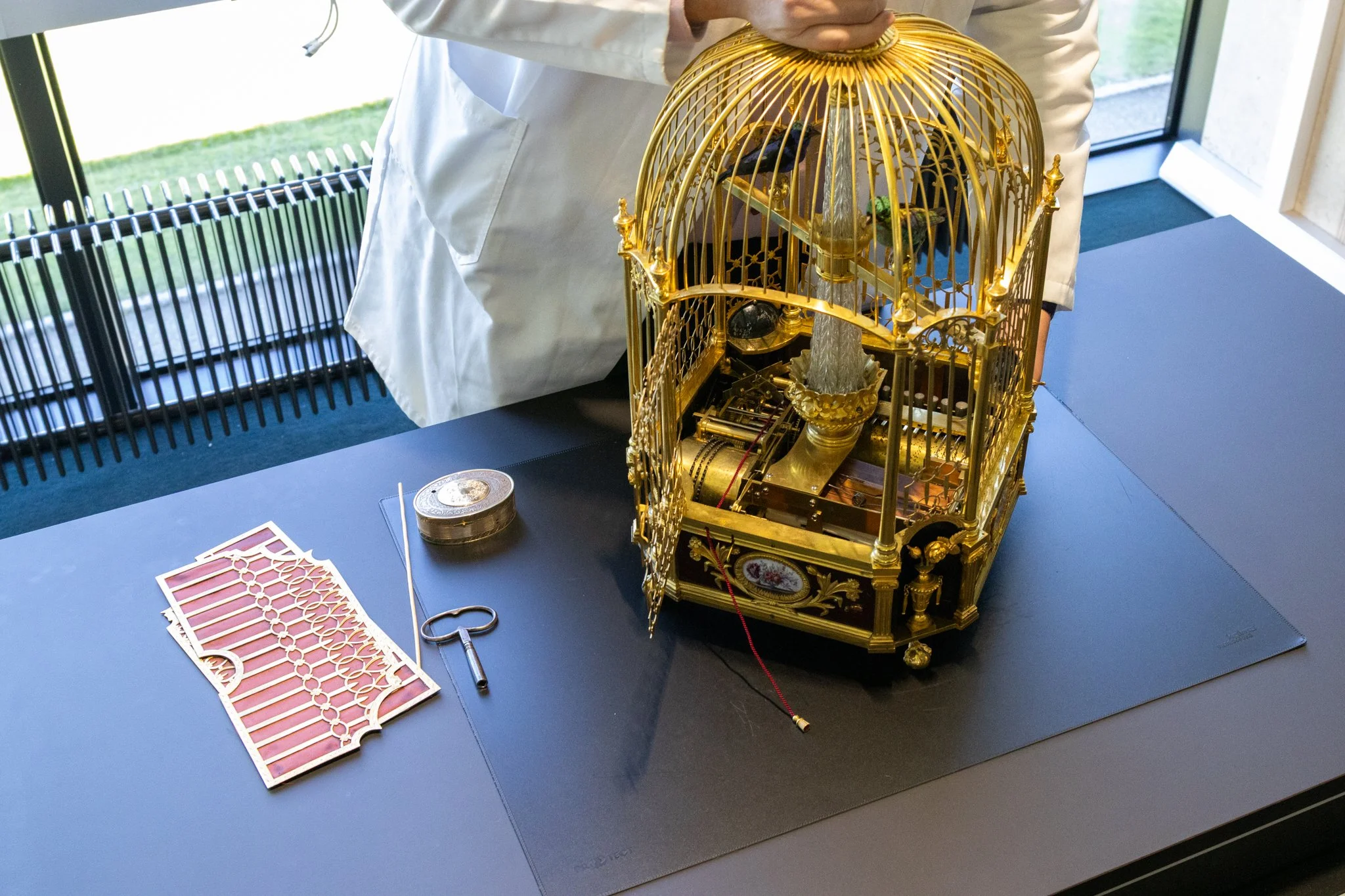

The Bird Cage

Next, we step into the realm of Jaquet Droz’s historic creations—where the brand’s legendary chiming bird mechanism takes center stage, the very birthplace of its pioneering spirit.

Invented in the 18th century, this remarkable piece remains fully functional to this day, a testament to its timeless craftsmanship. Every detail shines with realism: the birds themselves are crafted to look lifelike, while the mesmerizing water stream behind them adds an extra layer of enchantment. Designed for ceiling hanging, its dial is cleverly placed beneath the bird cage, ensuring easy time-reading from below.

Yet the most captivating feature lies in its movement and sound: the birds don’t just mimic the motions of real birds—they sing like them too, blending horological precision with whimsical artistry that defined Jaquet Droz’s legacy centuries ago.

Jaquet Droz’s Snuff Box: Where Luxury Meets Mechanical Whimsy

Among Jaquet Droz’s historic creations, the snuff box with a charming bird mechanism redefined 18th-century luxury. Beyond a decorative snuff container, it aimed to impress wealthy patrons by offering more than just elaborate ornamentation.

Its core is the brand’s signature ingenuity: a tiny, intricate bird mechanism. When activated, it brings the box to life—delight that ordinary fancy snuff boxes of the era lacked. For the elite, this was not just a practical accessory, but a status symbol to showcase wealth and taste for Jaquet Droz’s unique blend of mechanical precision and artistic charm.

Every detail, from the polished exterior to the hidden bird mechanism, reflected the brand’s commitment to turning daily luxury items into miniature art. It embodied the idea of transforming functional objects into wonders—a philosophy at the heart of Jaquet Droz’s craft for centuries.

Pocket Watches

Jaquet Droz’s historical pocket watches are a key highlight. The brand’s expertise goes beyond high-end traditional watchmaking—it excels in traditional crafts, with these watches as ideal showcases.

Two core techniques stand out: micro-enamel painting and micro-engraving. Micro-enamel painting requires precision: artisans apply layered, high-temperature-fired enamel to watch cases/dials, then paint intricate patterns (landscapes, figures, florals) for vibrant, durable portable art.

Micro-engraving displays top-tier skill: with special tools, artisans etch fine designs (geometric patterns, elaborate scenes) onto metal parts like case backs. Even up close, engravings stay sharp, proving mastery.

These pocket watches are more than timepieces—they blend high-end watchmaking with traditional artistry. Every detail reflects the brand’s commitment to preserving crafts, making each watch unique and precious.

Jaquet Droz’s Neuchâtel Clock: Where Century-Old Expertise Meets Boundless Imagination

The Neuchâtel clock vividly shows Jaquet Droz’s unmatched horological prowess—rooted in mastering clockmaking complications since its start. The brand has not only honed intricate clock mechanism skills but also refined these complexities for over two centuries.

This long commitment to innovation and precision makes it a trailblazer: it doesn’t just make timepieces, but brings nearly any imaginable horological concept to life. The Neuchâtel clock specifically reflects this capability—its design and complications showcase expertise forged through decades of iteration. With over 200 years of refinement, Jaquet Droz has turned “impossible” to “achievable,” making the clock a symbol of its ability to turn horological dreams into tangible, extraordinary works.

The Inner Workings of Jaquet Droz’s Automaton Wristwatches

After exploring historic creations, we visited Jaquet Droz’s watchmakers’ benches, where artisans opened an automaton wristwatch’s inner mechanism to reveal its intricate engineering.

At the watch’s core is a specialised mechanical module (separate from the timekeeping movement), made of tiny calibrated parts: gears, levers, springs, and camshafts. Activated via a case pusher, camshafts rotate—their lobes trigger levers, turning rotational motion into movement that animates dial elements (e.g., fluttering birds).

The module integrates with the main movement: it draws minimal power from the mainspring, ensuring smooth automaton motion without harming timekeeping accuracy. All components are hand-finished and tested (gears polished, springs calibrated, levers adjusted) for reliability in the compact case.

Artisans’ explanations showed the automaton’s “magic” comes from decades of horological expertise. Every detail (gear tooth size, cam lobe angle) relies on calculation and traditional craftsmanship, embodying Jaquet Droz’s blend of mechanical ingenuity and artistry.

Chiming Bird Model: A Clear View of Mechanical Ingenuity

The transparent chiming bird model gives an unobstructed view of Jaquet Droz’s iconic chiming bird mechanism. Through its clear casing, visitors see complicated gears and slender shafts work in sync—driving the bird’s lively movements. It also reveals how the bird’s motions match its singing: intricate air chambers produce lifelike chirps, with every bird movement timed to the sound.

It’s hard to believe this smoothly operating mechanism was invented over 200 years ago; its precision and creativity still feel ahead of its time, a testament to the brand’s historic innovation.

The Chiming Bird Watch: Miniaturizing a Complex Marvel

Next is the real Jaquet Droz wristwatch with this chiming bird mechanism—deepening awe. The same elaborate system of gears, shafts, and air chambers (easily seen in the model) is condensed into the tiny space of a wristwatch.

The miniaturization difficulty is immense: all components are scaled down without losing functionality (smaller gears, more delicate air chambers, thinner shafts) while keeping the bird moving lively and singing clearly. Fitting this complex mechanism into a wearable watch case is both a technical feat and a horological craftsmanship masterpiece.

Jaquet Droz Enamel Dials: A Fusion of Customization, Premium Materials, and Vibrant Colors

Enamel dials are a Jaquet Droz craftsmanship hallmark, blending artistry with horological precision. Each dial, with flexible themes, premium materials and vivid colors, reflects the brand’s pursuit of excellence.

Themes: Unlimited Creativity for Every Preference

Jaquet Droz’s enamel dial themes have no limits—any theme in any style is possible for diverse tastes. From classic motifs like floral patterns, geometric designs and landscapes to personalized concepts such as mythical creatures, cultural symbols and custom stories, skilled artisans (equipped with artistic literacy and enamel mastery) turn these ideas into detailed, story-telling dial designs.

Materials: A Blend of Luxury and Texture

Jaquet Droz uses premium materials for its enamel dials to balance luxury and texture. For precious stone dials, carefully selected diamonds, sapphires or rubies—chosen for their clarity, color and cut—are inlaid in precise patterns on the enamel surface; the combination of enamel’s smoothness and the stones’ brilliance adds a touch of opulence. The core of each enamel dial is high-quality enamel, made by fusing glass powder onto a copper or gold base at high temperatures, which ensures a smooth, glossy finish and strong durability, as enamel resists scratches, fading and corrosion. Additionally, artisans create different textures on the enamel surface using techniques like engraving, embossing or stippling to add subtle patterns or raised details, breaking the monotony of the smooth surface and enhancing depth—for example, an engraved floral texture can catch light to create dynamic visual effects.

Colours: Endless Combinations for Vivid Expressions

Color highlights Jaquet Droz’s enamel dials—any colour combination is achievable via advanced techniques. Enamel is tinted with metal oxides to produce a wide range of hues, from soft pastels like baby pink and mint green to bold shades such as deep red and royal purple. Artisans are skilled in color matching, able to create gradient effects where one color fades smoothly into another or contrasting combinations that make dial motifs stand out—like a deep blue base paired with gold florals, or a pink-white gradient with silver engravings. Moreover, dial colors are carefully chosen to complement the watch’s case, strap and movement, ensuring a cohesive overall aesthetic.

Jaquet Droz Engravings: Boundless Themes Crafted by In-House Artisans

Engravings are key to Jaquet Droz’s horological artistry, giving timepieces unique character. Its engravings stand out for two strengths: free thematic creation and in-house handcraftsmanship.

For themes, any theme is possible to meet diverse client needs. From classic styles (floral vines, 18th-century geometric patterns, landscapes) to personalized designs (family crests, milestone symbols, memory illustrations), the team turns concepts into detailed art—backed by engravers’ versatility in line engraving, relief carving.

Notably, all engravings are by Jaquet Droz’s in-house artisans, ensuring quality. These artisans train for years to master pressure, precision and creativity for tiny watch parts (case backs, bezels, movement plates, dials). Unlike cold machine engravings, handcrafted ones have warm, unique marks (line depth variations, hand-mirrored curves) with deliberate strokes, carrying handcraft soul.

This mix of boundless themes and in-house handcraft makes Jaquet Droz’s engravings wearable art. Each engraved timepiece is a personal statement, blending client vision and artisan skill, and a testament to the brand’s legacy of preserving traditional horological crafts.

4K Live Video Conferencing in Jaquet Droz Factory: Interactive Links for Custom Watchmaking

In Jaquet Droz’s custom watchmaking, factory-based 4K live video conferencing is a key interactive bridge—connecting clients directly with artisans crafting their timepieces. With ultra-high-definition quality and real-time interaction, it keeps clients involved in every customization step. Below is how three core factory scenarios work: Studio 8, At the bench, and Green-wall conference room.

Studio 8: The "Custom Consultation Hub" for Comprehensive Communication

Studio 8 is a factory 4K space for initial/mid-stage custom consultations. Its "high-spec hardware + standardized layout" enables clear communication between clients, consultants, and remote artisans. Equipped with 4K cameras (prototypes, swatches, sketches), professional lighting (enamel, engravings, gems), and acoustic optimization (reducing factory noise), it lets clients remotely check customization options.

For example, during dial customization, 4K cameras zoom in on enamel samples/engraving drafts; consultants/artisans explain materials and craft feasibility in real time. Clients share preferences (e.g., adjusting engraving depth) and view revisions via live stream. It also supports "client + multi-department artisan" meetings to align decisions with client vision and brand standards.

At the bench: The "Craft Visibility Window" for Real-Time Artisan Interaction

Set at factory workbenches, "At the bench" is the core of interactive customization—it lets clients watch their timepieces being crafted in real time and communicate with artisans. The scene has tools, half-finished movements, and custom components (e.g., engraved case backs). A compact 4K camera (mounted/handheld) captures steps (enamel polishing, chiming bird assembly), while a wireless mic lets artisans explain techniques and answer questions.

For instance, if a client commissions a watch with an engraved family crest, the 4K stream shows the engraver sketching, selecting chisels, and cutting. Clients can ask, "Can the crest’s edges be rounder?" and artisans adjust in real time. This builds trust and makes customization participatory.

Green-Wall Conference Room: The "Custom Scenario Simulation Space" for Holistic Vision Sharing

The factory’s Green-wall conference room is a flexible 4K space for simulating final custom watches and cross-stage coordination. Its green screen, paired with 4K cameras and real-time keying, overlays custom watch designs (e.g., 3D models with chosen dials/straps) onto virtual backgrounds (e.g., formal events) to visualize the finished piece.

During final reviews, artisans present half-finished watches via live stream; the green screen shows the watch with different straps or when worn. Clients discuss tweaks (e.g., adjusting case size) with designers and watchmakers. It also supports "virtual factory tours" (enamel workshops) to help clients understand the full craft chain, ensuring a holistic view of the timepiece.

We sincerely thank Jaquet Droz for welcoming us on such a fascinating journey—one that allowed us to deeply explore the boundless possibilities of the brand’s exceptional watchmaking capacity. From the intimate access to its craftsmanship processes to the insights into its innovative spirit, every moment of this experience has underscored why Jaquet Droz remains a paragon of horological excellence. This journey not only enriched our understanding of fine watchmaking but also strengthened our admiration for the brand’s dedication to preserving and advancing its legacy.