Visiting L'Epée 1839 in Delémont

L'Epée 1839: Inheriting Clockmaking Art Rooted in Delémont, Switzerland

L'Epée 1839, a brand with nearly 200 years of watchmaking heritage, has its manufacturing base in Delémont, a small northwestern Swiss town. Unlike big Swiss cities, Delémont is tranquil and time-honored, this calm environment is perfect for L'Epée 1839’s creative clockmaking.

Entrance Displays

At the entrance of L'Epée 1839 office, a humble display area greets visitors at the entrance. No flashy lights or grand decor, this unassuming space holds a few signature timepieces.

Design and Development

L'Epée 1839’s entire watch manufacturing process is carried out across two separate factory buildings. Our visit began with the first factory, where the design studio— the creative heartbeat of all the brand’s timepieces—takes center stage. This is where every watch’s inspiration comes to life, and also serves as a key space for client communication. Here, their team dives into the details of new creations with clients, discussing everything from design aesthetics to functional preferences, ensuring that each custom or new piece fully aligns with the client’s vision before moving forward to the manufacturing stage.

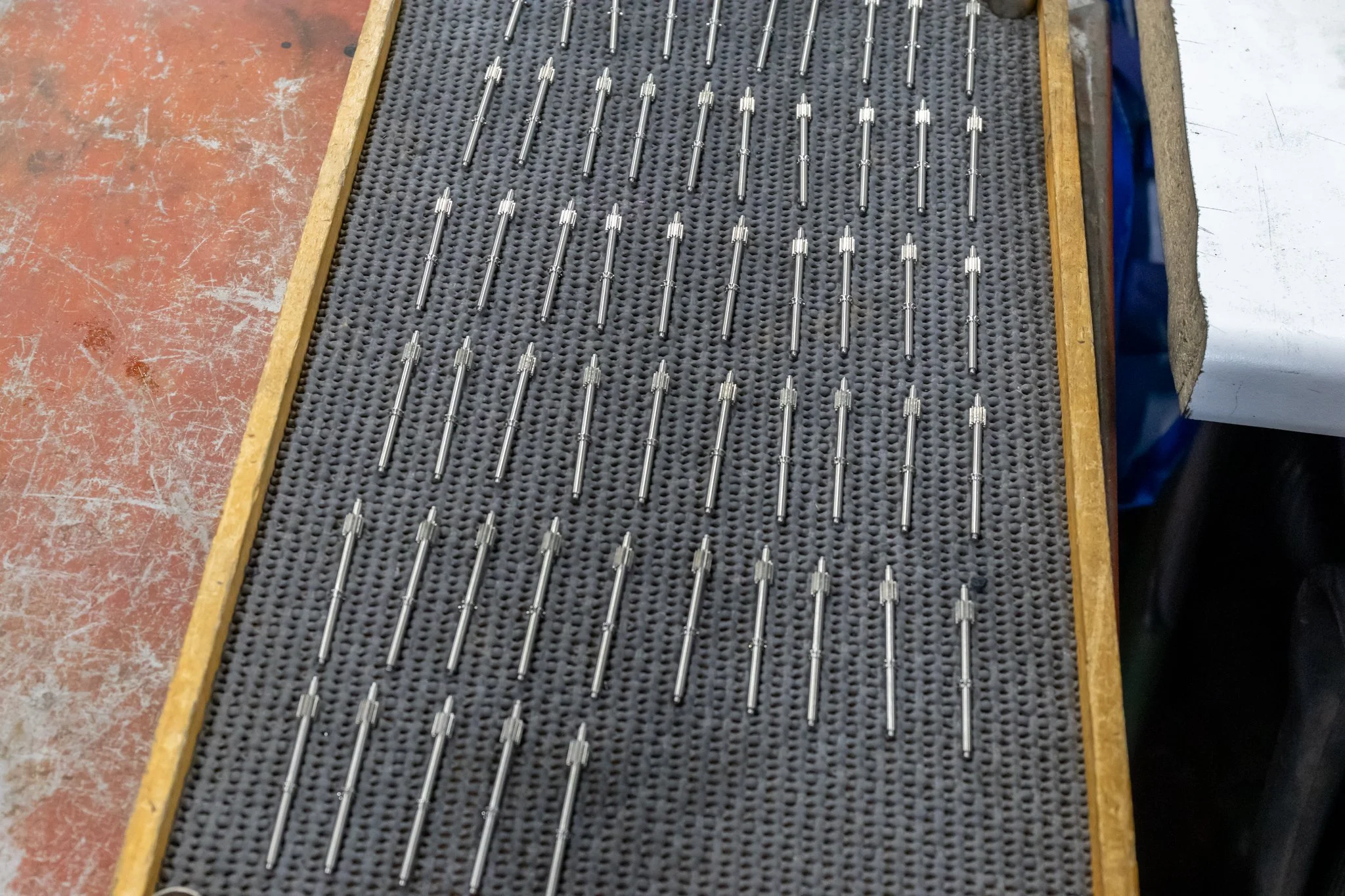

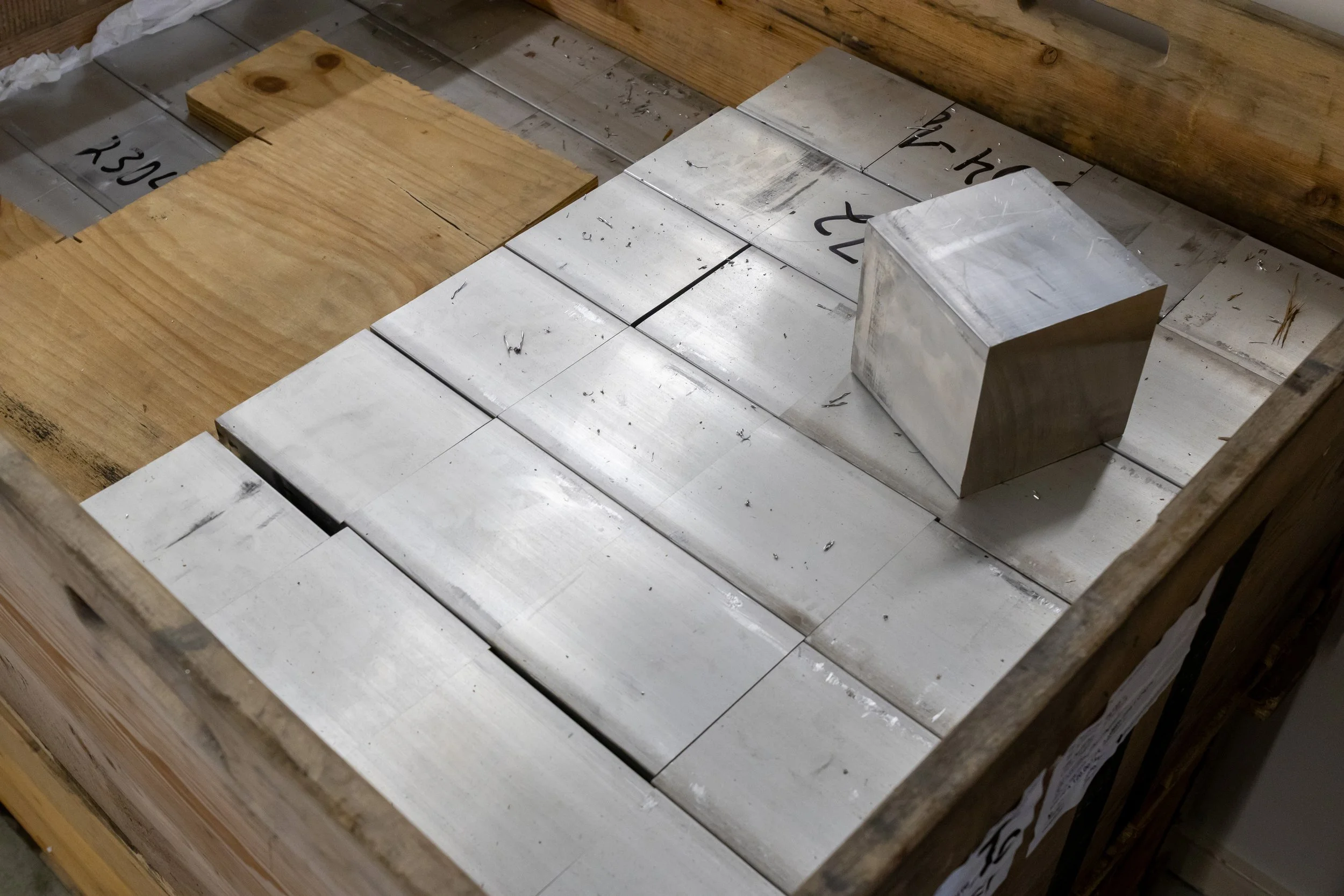

Lathe Area: Shaping Raw Materials into Craft

Then we visited the lathe area—where design ideas turn into tangible parts. Inside, the hum of machinery filled the air: raw materials (solid metal blocks, alloy rods) were secured onto lathes, then precision-cut and shaped into components for the next production stage.

The variety of raw material and machinery sizes stood out: small lathes handled delicate parts, while larger ones processed bulky blocks—proving L'Epée 1839’s ability to “turn anything imagined into reality.”

Piles of metal chips (turning byproducts) lay beside machines. These are not waste: the team collects them to recycle for future use.

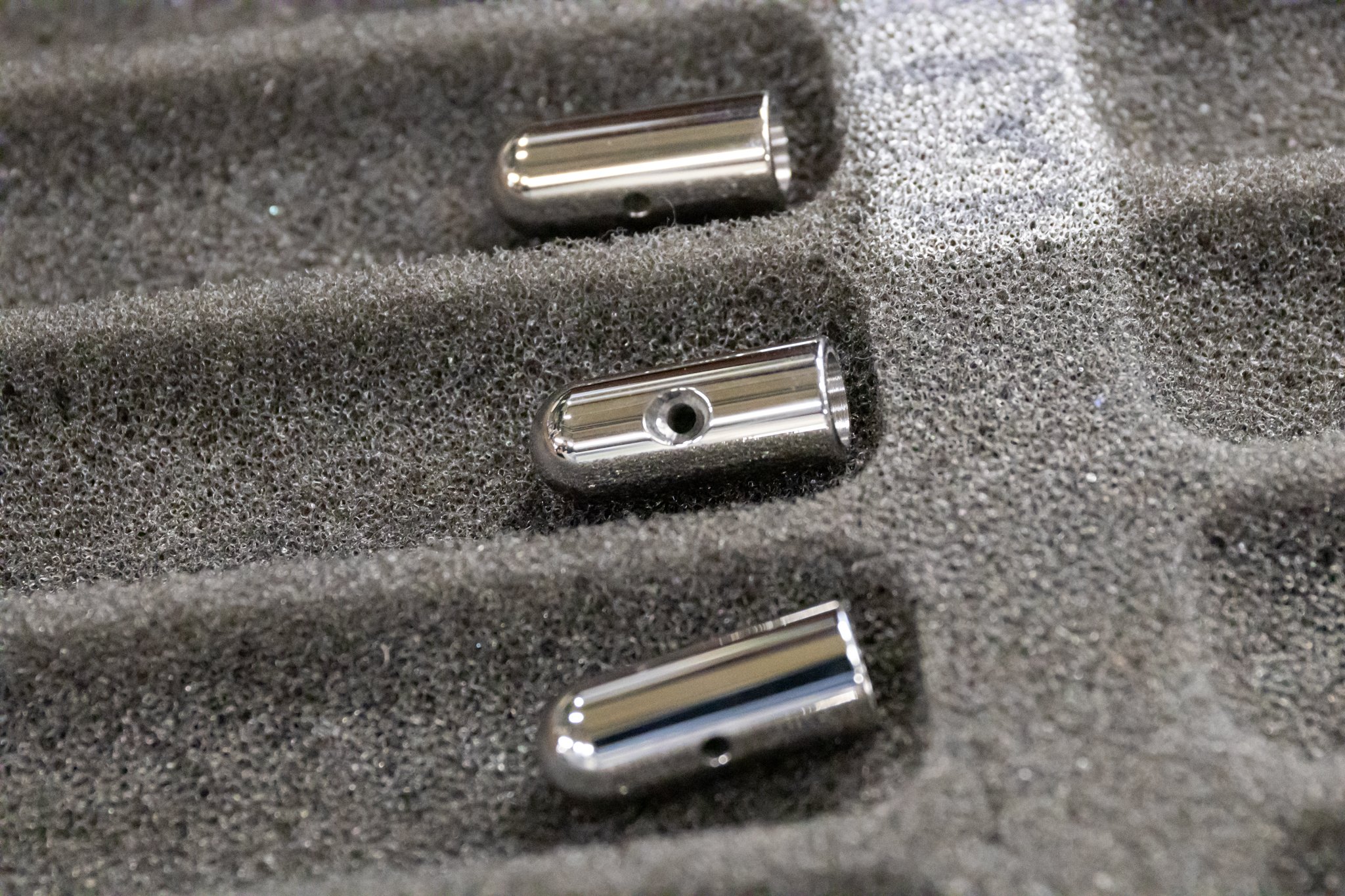

Polishing & Finishing Area: Craftsmanship in Every Detail

This is the polishing and finishing area, where every component undergoes refinement and decorative touches—all done by human hands. The craftsmanship here emphasises manual skill, ensuring each piece meets the brand's high standards of elegance.

Take a look at the specialized equipment that supports this meticulous work: there’s the Côtes de Genève machine, which creates the iconic wave-like patterns synonymous with luxury watchmaking; the large lapping machine, designed for achieving ultra-smooth, flat surfaces on metal components; belts of different grit grades, tailored specifically for creating satin finishes—each grade adjusting the softness and texture of the component’s surface; and the sandblasting machine, used to craft unique matte or frosted textures for selected parts.

Together, these tools and the skilled hands of craftsmen transform basic components into refined, visually appealing pieces, laying the groundwork for the high-quality timepieces L'Epée 1839 is known for.

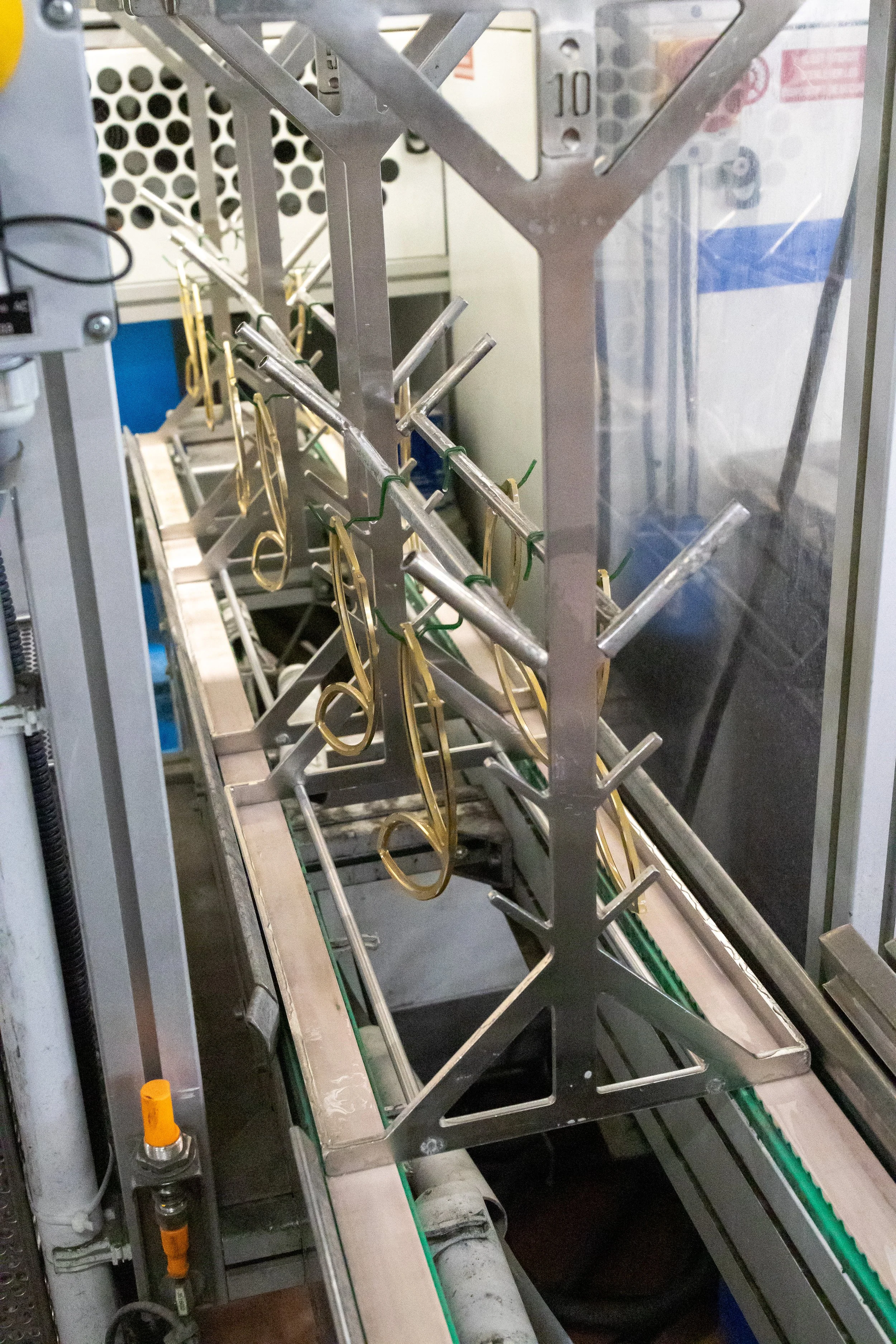

Cleaning Room: A Critical Step in Watchmaking

This is the cleaning room—an often understated yet indispensable space in watch manufacturing process. Here, the core task is simple but vital: ensuring every watch component is thoroughly cleaned before moving on to the next stage of finishing or decorating.

Why is this step so critical? Between most finishing processes (like polishing, lapping) and decorating techniques (such as Côtes de Genève engraving or sandblasting), tiny residues—from metal dust and oil to minute fragments of polishing compounds—can cling to the component’s surface. If left unremoved, these impurities would ruin the precision of subsequent work: they might scratch delicate surfaces during satin finishing, disrupt the evenness of decorative patterns, or even interfere with the fit and function of parts later in assembly.

In the cleaning room, components go through rigorous, precision-controlled cleaning processes—using specialised solutions and tools that eliminate all residues without damaging the metal or compromising the details crafted in earlier stages.

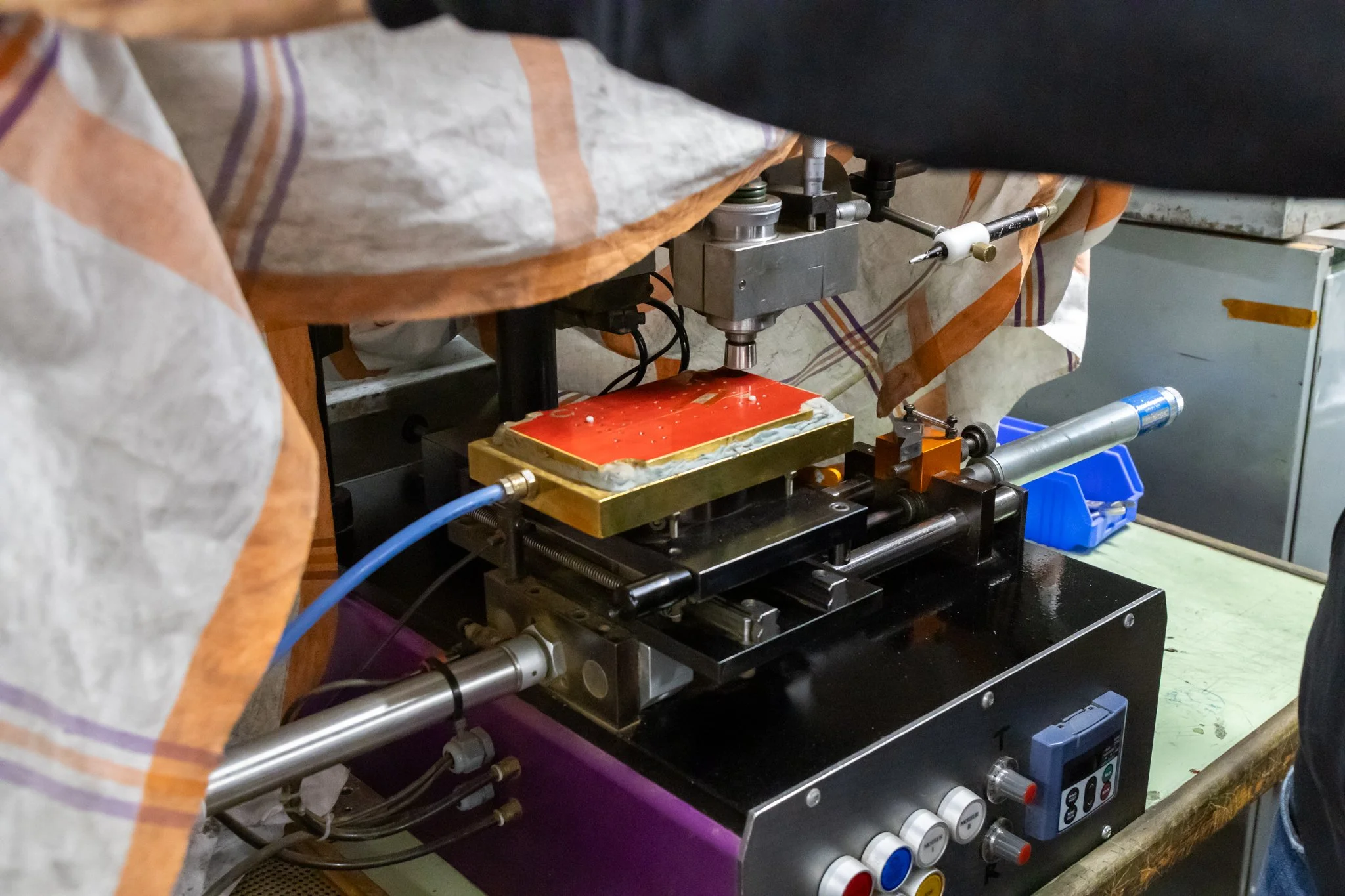

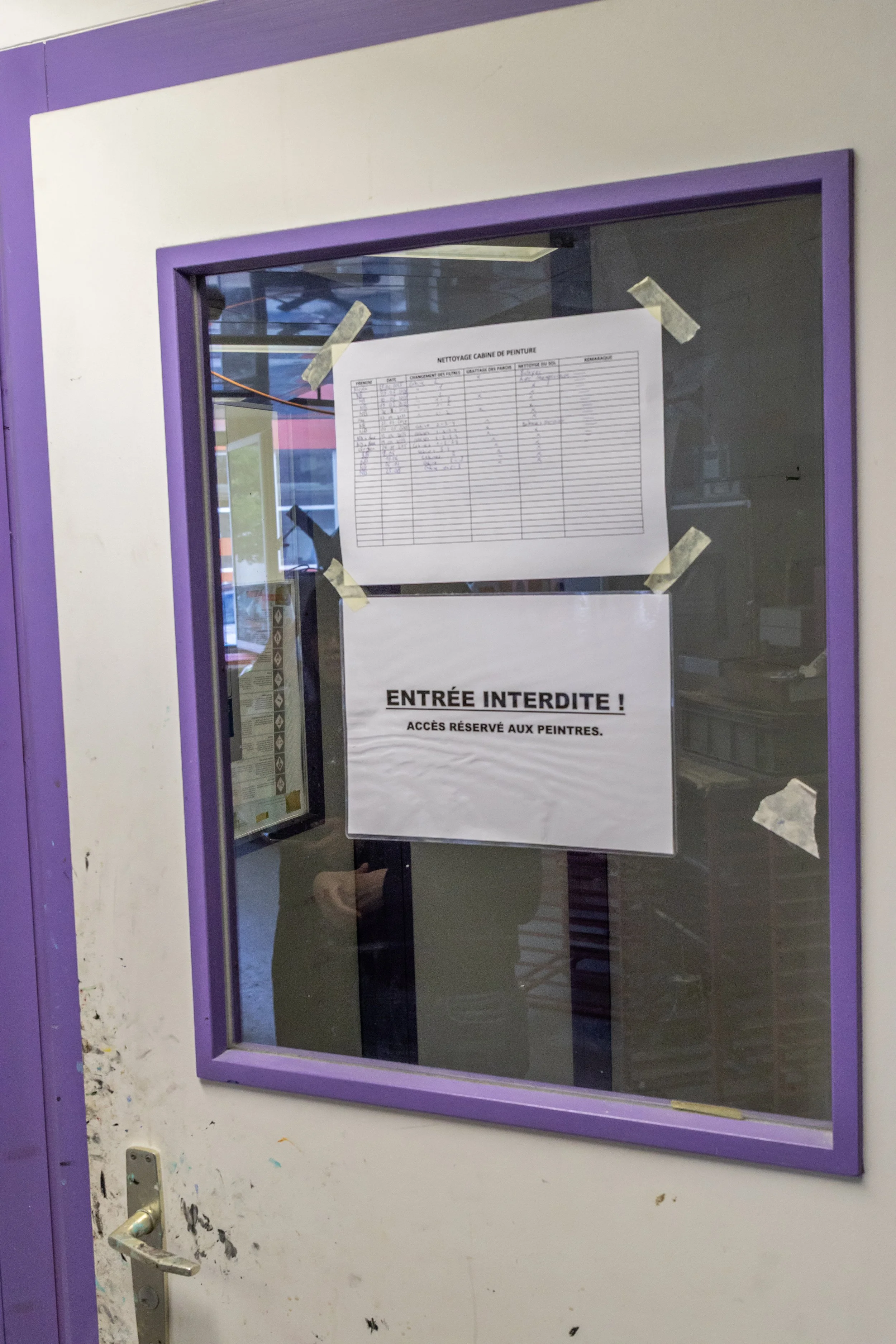

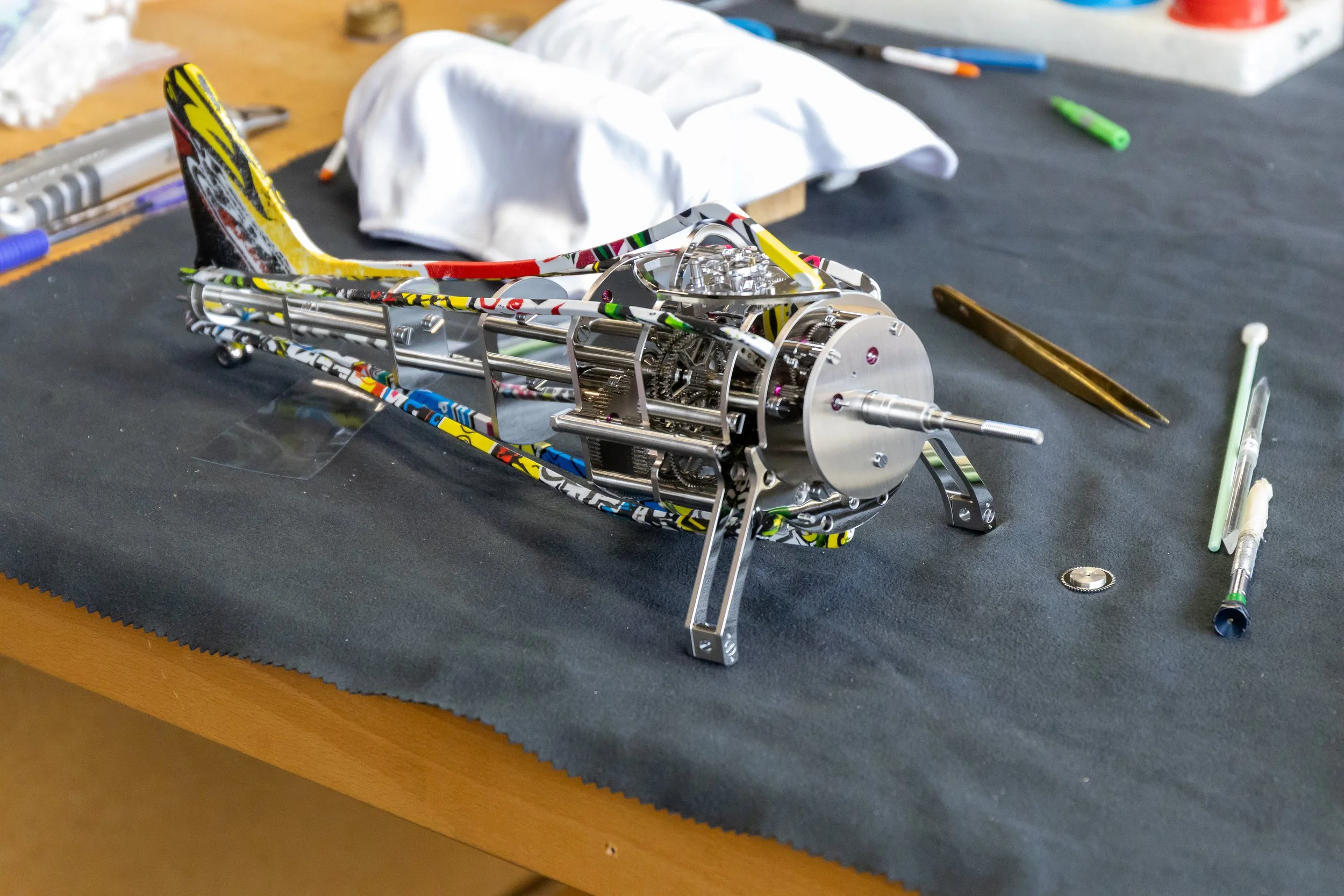

Lacquering & Painting Room: Where Color Magic Unfolds

This is the lacquering and painting room— the very space where L'Epée 1839 weaves its “magic of colours” into watch components. Far beyond simple coloring, this room transforms functional parts into vivid, artistic elements that define the brand’s timepieces.

At the core of this process is a computerised system for managing all coloring materials, ensuring precision and consistency in every batch. The range of materials here is impressive: from vibrant, glossy lacquers that add bold pops of color to ultra-durable enamel coatings built to withstand the test of time. Each component enters this room like a blank canvas—plain metal waiting to be transformed— and exits as a small masterpiece of art: a case with a rich, deep lacquer finish, a dial adorned with smooth enamel, or a detail piece with a subtle, layered color effect.

What also stands out is the brand’s care for its artists. The room features a pressurised area secured by a double-door system, and every craftsman working here is equipped with safety suits and masks. This thoughtful setup protects their health while they focus on creating the brand’s colorful magic, blending artistry with responsibility in every brushstroke and spray.

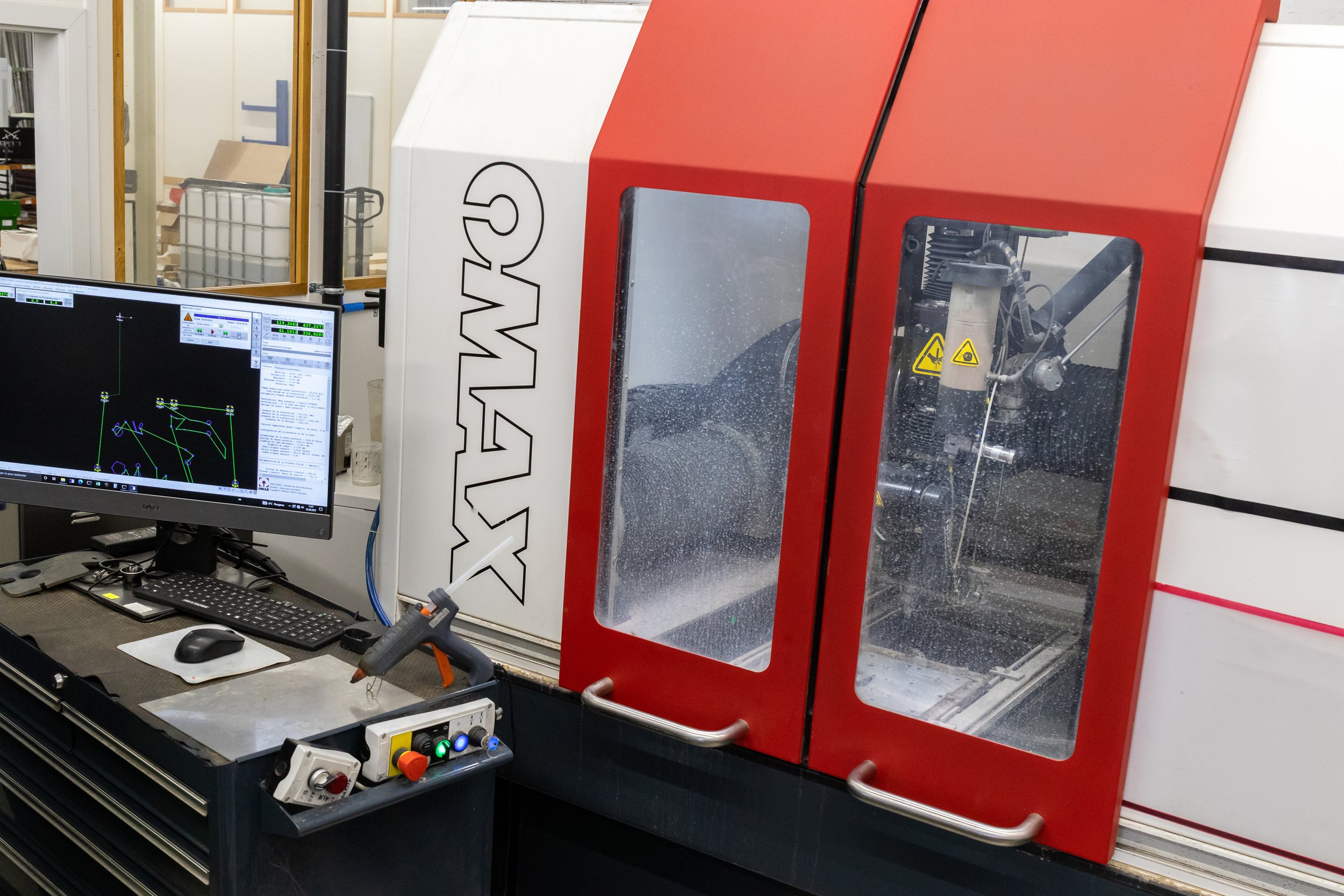

L'Epée 1839's Milling Machine Area: Expanding Creative Possibilities

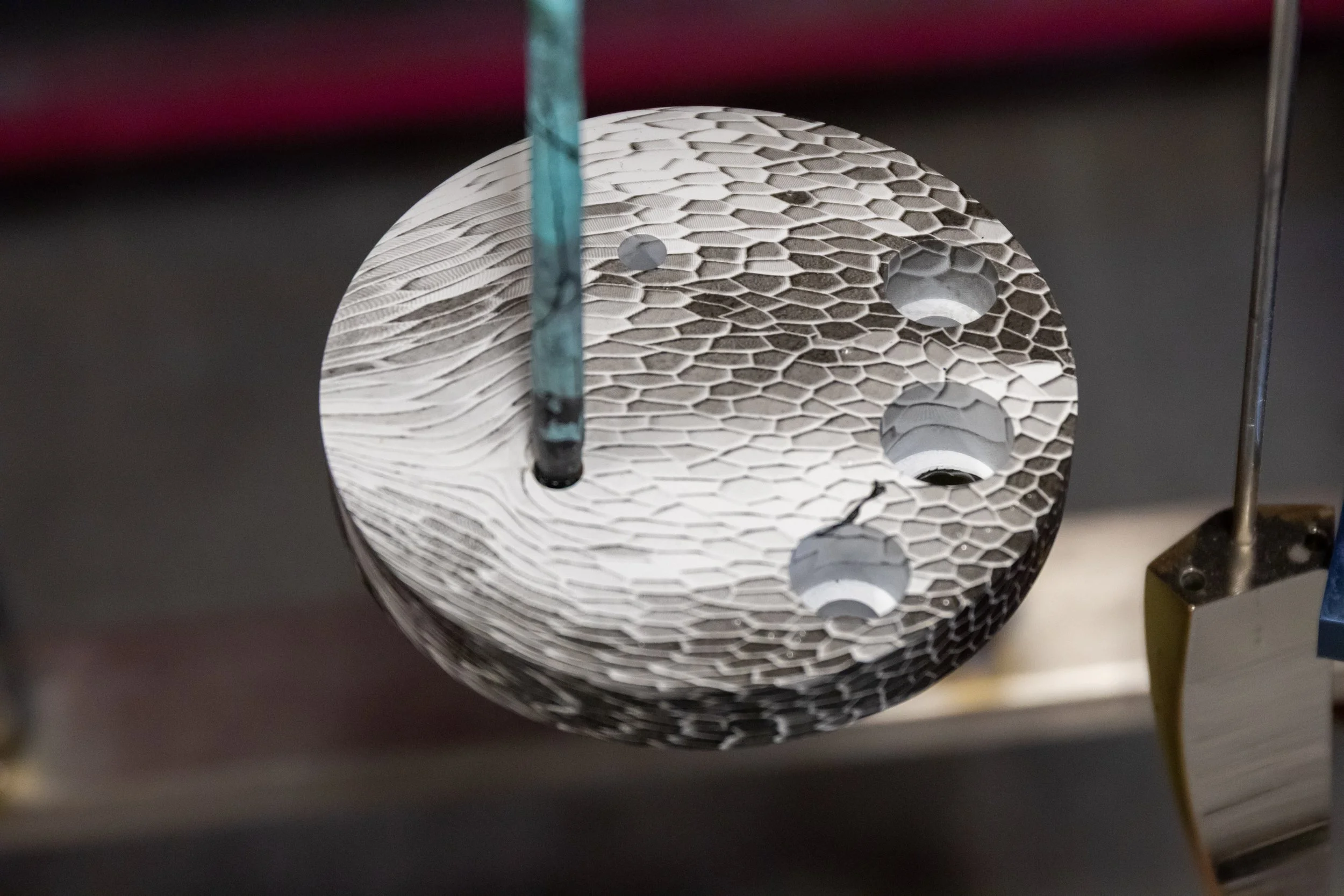

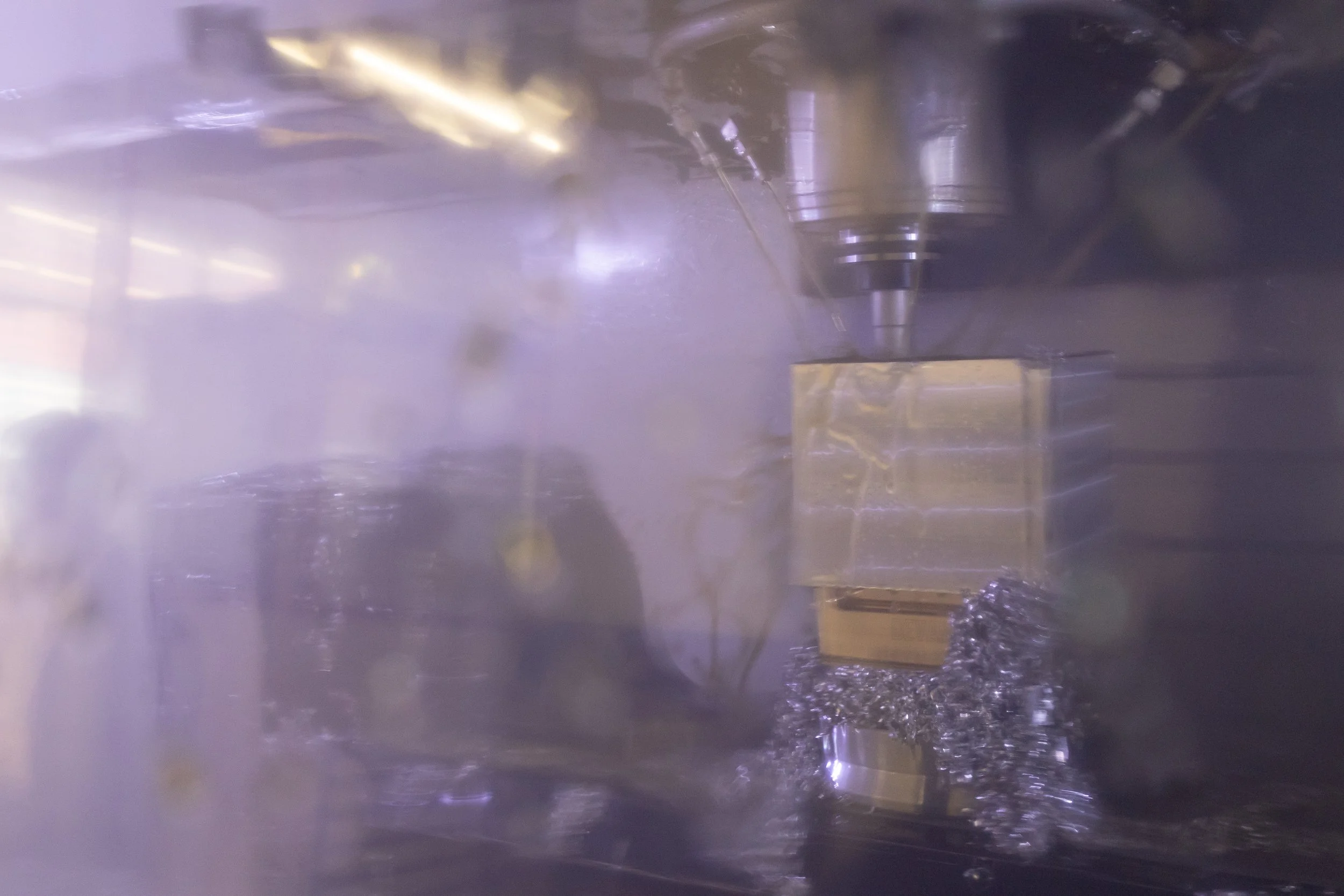

After the lathe area, we visited the milling machine area—a key space that boosts L'Epée 1839’s ability to turn bold designs into intricate watch components. Here, the brand has a wide range of milling machines, including various multi-axis and size options, each built to handle different manufacturing complexities.

These machines elevate the brand’s creativity: multi-axis models offer unmatched precision, carving complex geometries, delicate grooves and intricate details that basic tools can’t achieve. From tiny movement parts to sculptural clock cases, the diverse machines let L'Epée 1839 create almost anything.

Watching the process is striking: plain raw material blocks are secured to machines, which remove excess material with accuracy. Bit by bit, blocks become components with sharp edges, curved surfaces or intricate patterns—showcasing advanced machinery and the brand’s craftsmanship. This area turns creative ambition into reality, strengthening L'Epée 1839’s reputation for pushing watch design limits.

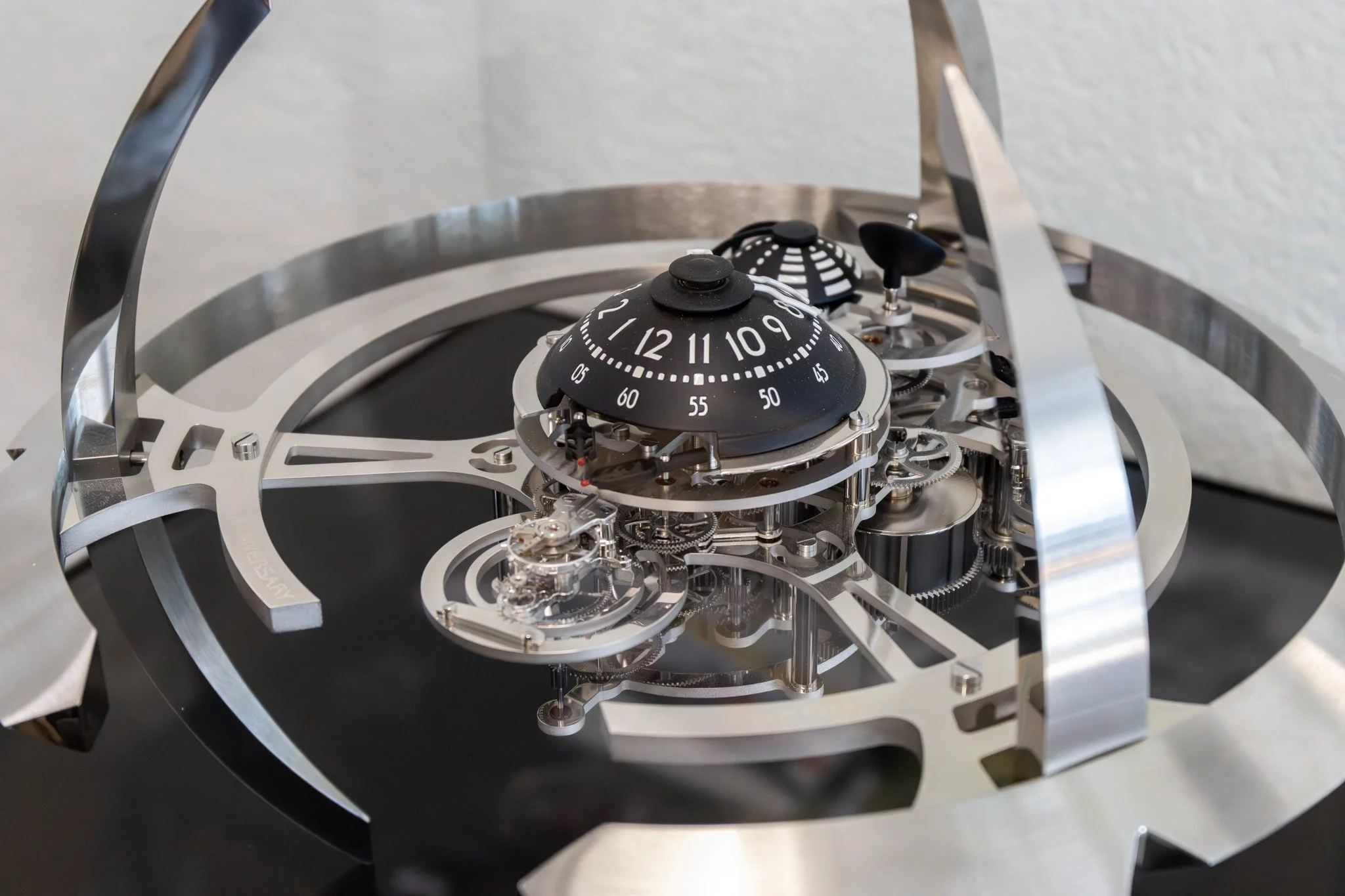

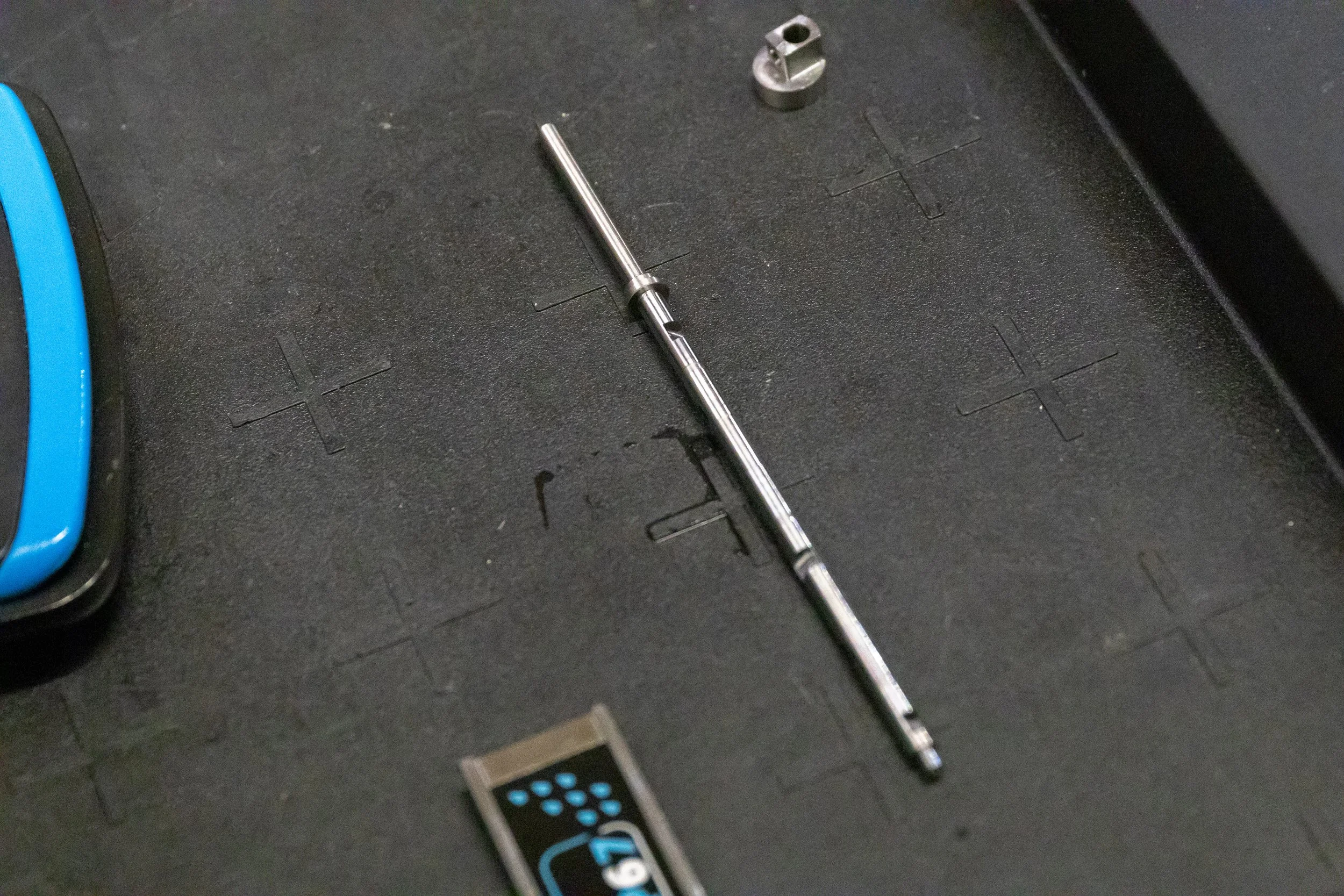

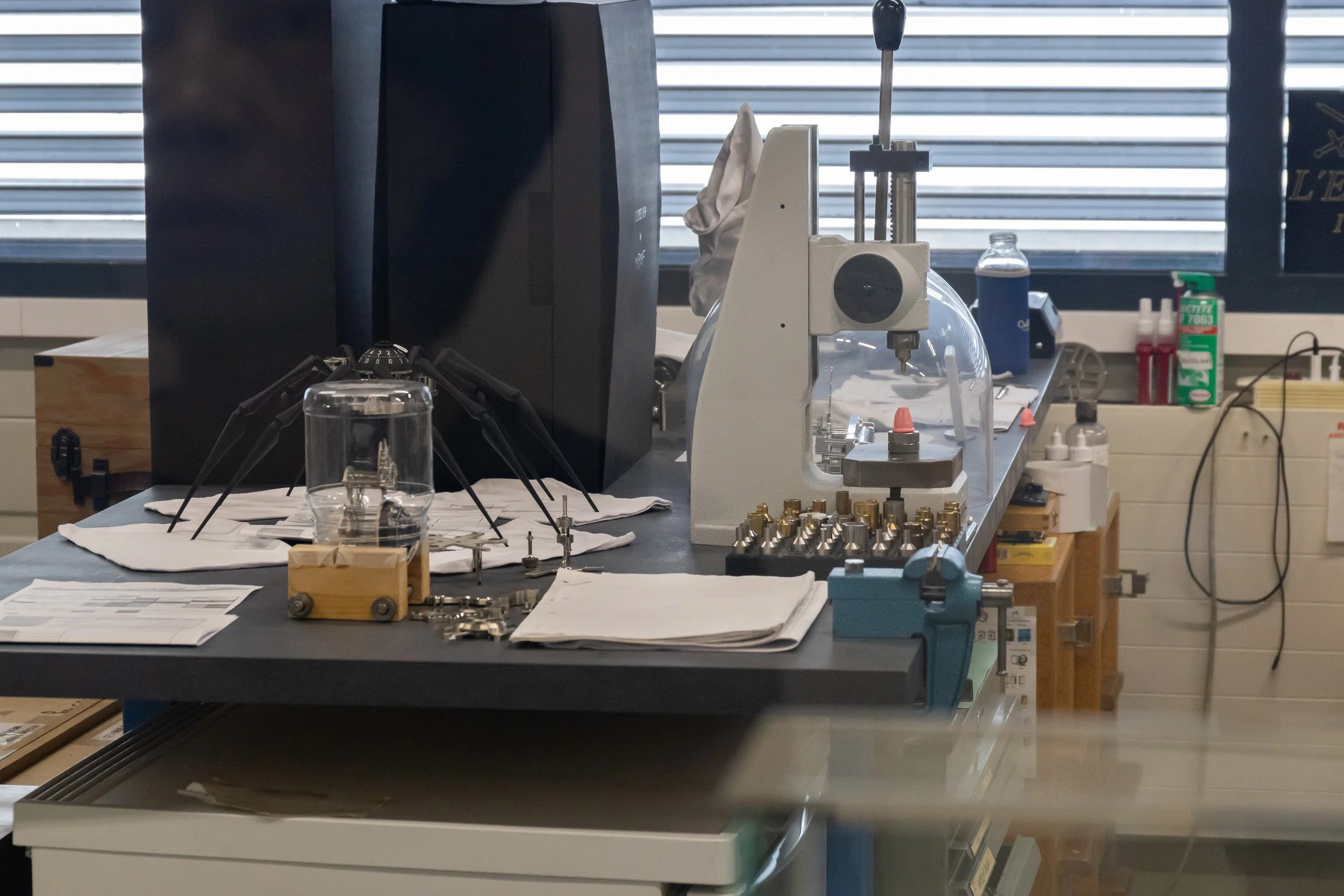

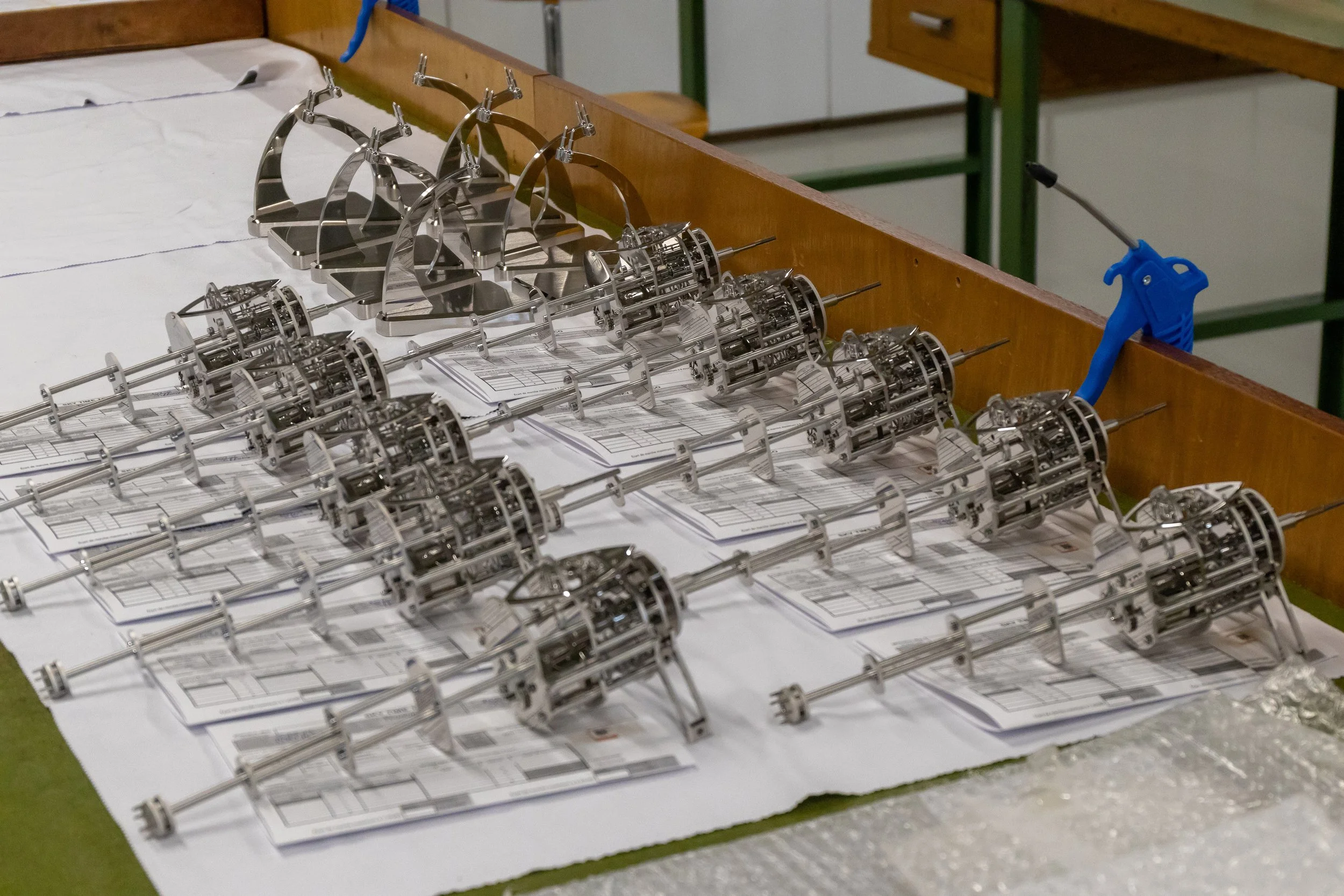

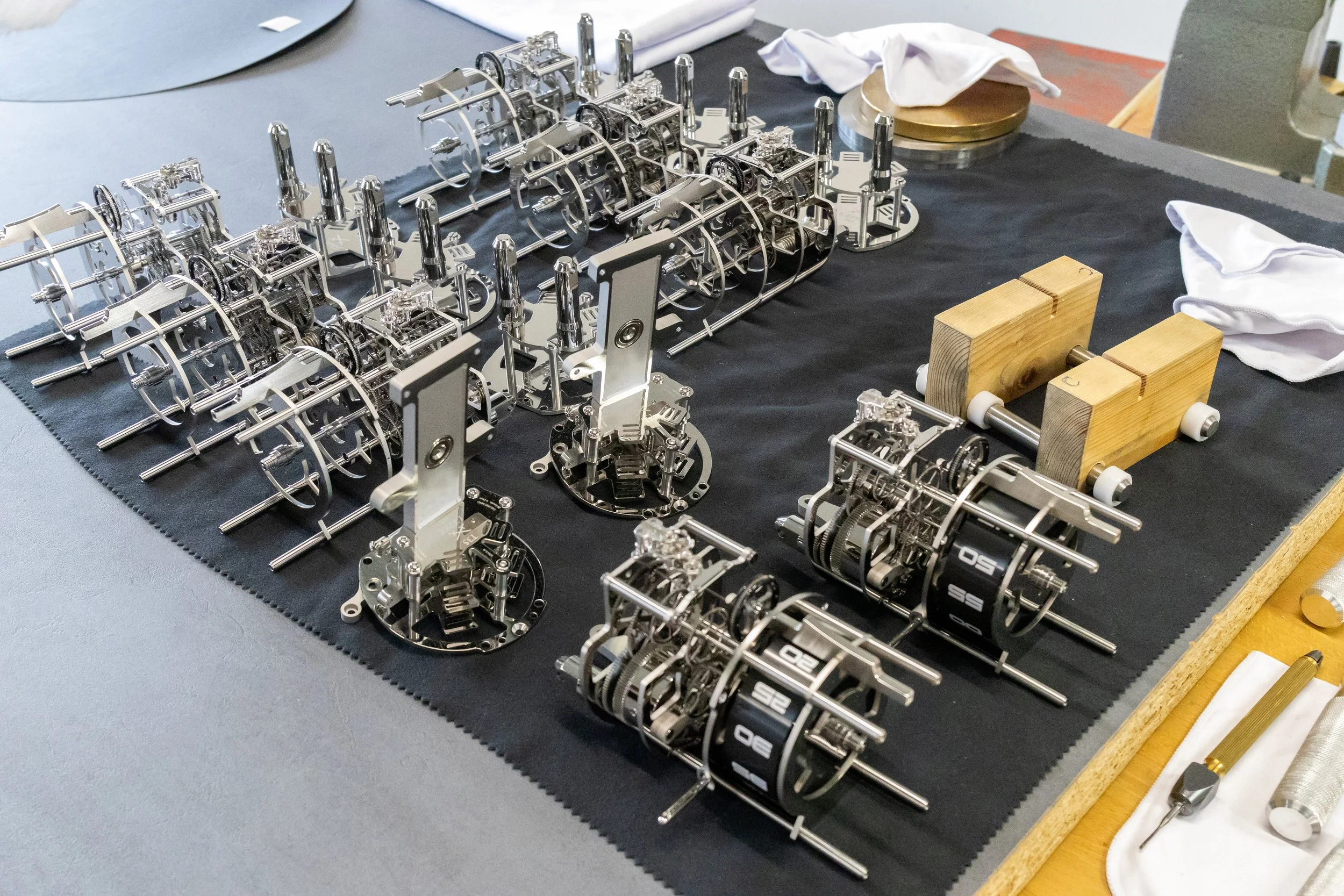

Assembly Area: The Final Birthplace of Iconic Timepieces

We have now arrived at the culmination of the watchmaking journey: the assembly area. Here, components that have undergone meticulous lathe processing, milling, polishing, and lacquering come together, their individual stories converging as skilled horologists artfully handcraft them into complete timepieces.

The assembly area feels familiar: you’ll spot components like polished cases, coloured lacquered parts, or cleaned movement pieces—all from L'Epée 1839’s iconic timepieces.

Clockmakers sit at workbenches, precisely joining gears, dials and cases. They ensure proper installation, accurate timekeeping, and protect each piece’s unique texture. When these multi-processed components become a complete timepiece, a classic work carrying the brand’s craftsmanship is officially born.

We would like to express our sincere gratitude to L'Epée 1839 for warmly welcoming us to their factory. During this visit, we had the valuable opportunity to get an up-close look at their fully in-house clockmaking process, deeply explore the boundless craftsmanship and innovative spirit behind their extraordinary creations, and witness firsthand how they honor and live up to their profound clockmaking heritage since 1839—seamlessly blending time-honored horological knownledge passed down through generations with cutting-edge innovations. This immersive experience left us with a profound and memorable impression.